company-profile-module $!{companyProfile}

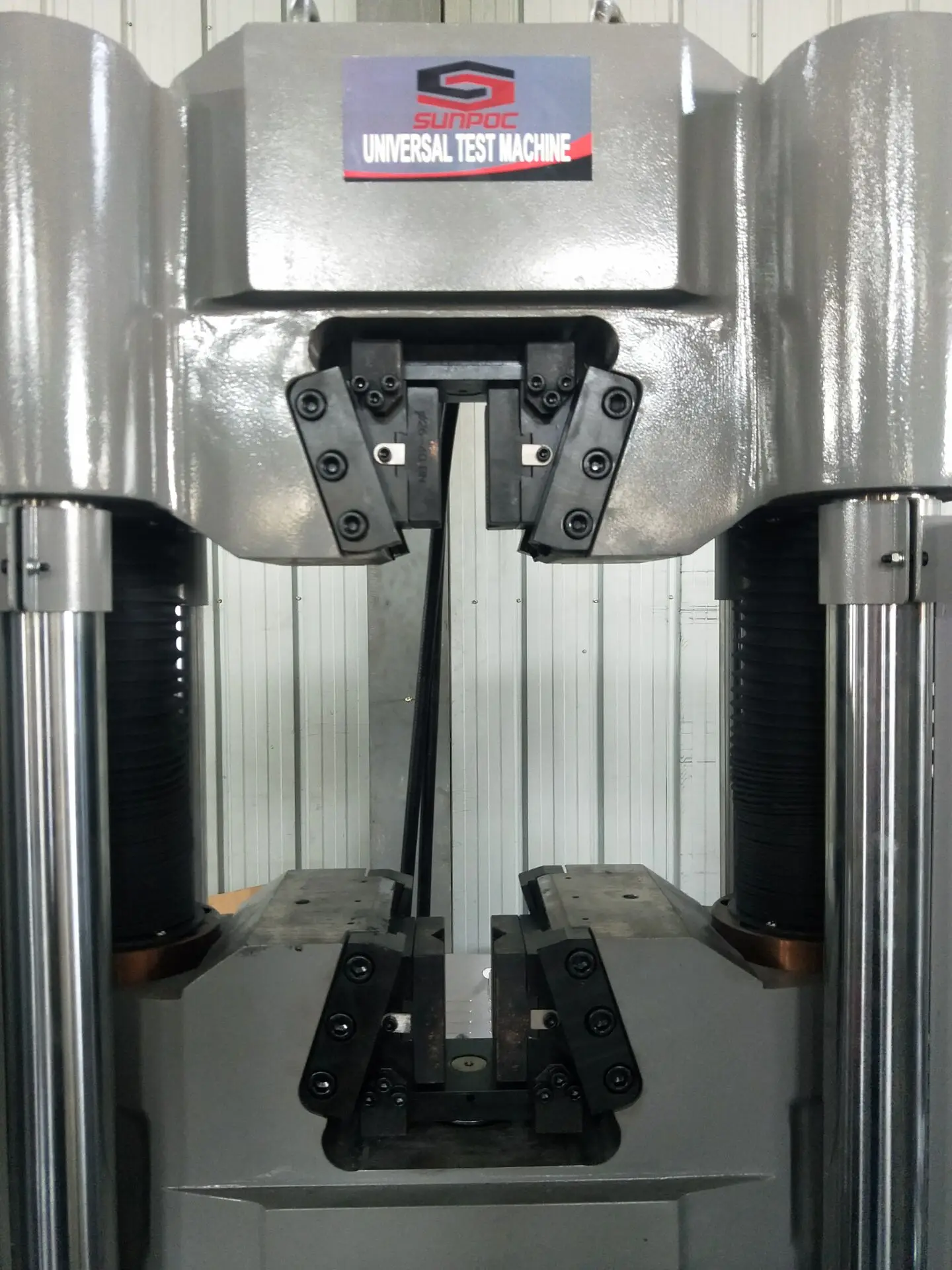

Servo hydraulic steel tensile testing machine tensile testing machine

Popular

Popular in

-

>=1 Sets

$14,560.00

- Use:

- Auto Testing Machine Plastic Testing Machine Compression Testing Machine Strength Testing Machine Tensile Testing Machine Bending Testing Machine Deformation Testing Machine Universal Testing Machine

- Inventory Status:

-

In Stock

- Lead time:

-

Quantity(Sets) 1 - 1 >1 Lead time (days) 7 Negotiable

- Customization

-

Customized packaging (Min. Order: 1 Sets)Customized logo (Min. Order: 1 Sets)

More

Graphic customization (Min. Order: 1 Sets) Less

Product details

Company profile

Overview

Essential details

- Warranty:

-

3 years

- Customized support:

-

OEM, ODM, OBM

- Place of Origin:

-

Guizhou, China

- Brand Name:

-

SUNPOC

- Model Number:

-

WAW-600D

- Power:

-

Hydraulic

- Product Name:

-

Hydraulic Universal Testing Machine

- Model:

-

Universal Testing Machine

- Capacity:

-

600KN Hydraulic Universal Testing Machine

- Accuracy:

-

±1%

- Resolution:

-

1/500000

- Clamp:

-

Hydraulic Auto Clamp

- Press Plate:

-

160MM

- Pull Space:

-

800mm

- Compression Space:

-

550mm

- Keyword:

-

Hydraulic Testing Machine

Packaging & delivery

- Lead time :

-

Quantity(Sets) 1 - 1 >1 Lead time (days) 7

Online Customization

Servo hydraulic steel tensile testing machine tensile testing machine

Product Description

WAW-D Series Hydraulic Universal Testing Machine Application

WAW-D series electro-hydraulic universal testing machine is an important instrument and equipment for testing the physical properties, mechanical properties, process properties, structural properties and internal and external defects of various materials and their products. It can realize tensile, compressive, bending, shearing and other types of tests on metal or non-metallic materials, and can automatically obtain the performance indicators such as tensile strength, yield strength, specified non-proportional elongation strength, elastic modulus, etc. , can complete constant-rate loading, constant-rate deformation, constant-rate displacement, constant-rate strain and other closed-loop control. This machine is accurate, powerful, easy to operate, stable and reliable. It is widely used in precise material research, material analysis, material development and quality control in universities, scientific research institutes, testing institutions, aerospace, industry, metallurgy,machinery manufacturing, transportation construction, construction and building materials and other industries. The process qualification performance verification test of materials or products can be carried out.

Standard model | WAW-100/300D | WAW-600D/1000D | WAW-1500D/2000D | ||

Columns | 6 columns(4 Stand columns,2 guide screw) | 6 columns(4 Stand columns,2 guide screw) | 6 columns(4 Stand columns,2 guide screw) | ||

Max.force | 100kN/300kN | 600kN/1000kN | 1500kN/2000kN | ||

Grade | 1 | ||||

Testing force range | 2%-100%FS | ||||

Force resolution | 1/500000 | 1/500000;1/300000 | 1/300000 | ||

Testing force accuracy | ±1% | ||||

Displacement resolution | 0.01mm | ||||

Displacement accuracy | ±0.5% | ±0.5%;±1% | ±1% | ||

Deformation range | 1%-100%FS | ||||

Deformation resolution | 1/500000mm | 1/50000mm;0.001mm | 0.001mm | ||

Deformation accuracy | ±0.5% | ±0.5%;±1% | ±1% | ||

Wedge clamp | hydraulic auto clamp | hydraulic auto clamp | hydraulic auto clamp | ||

Round specimen | Φ13-Φ20 | Φ13-26 Φ26-40 | Φ15-30 Φ30-55 Φ55-70 | ||

Flats specimen thickness | 0-15mm 15-30mm(optional) | 0-15mm 15-30mm(optional) | 10-40mm 40-70mm | ||

Flats specimen wide | 75mm | 90mm | 100mm | ||

Press plate size | Φ120mm | Φ160mm | Φ160mm | ||

Pull space | 800mm | 800mm/950mm | 1000mm | ||

Compression space | 550mm | 550mm/700mm | 680mm | ||

Test wide | 500mm | 500mm/560mm | 680mm | ||

Table size(mm) | 660*540 | 660*540/810*600 | 810*500/720*500 | ||

Machine size(mm) | 690×660×2000, oil sources1200×680×750 | 690×660×2000, oilsources1200×680×750 | 690×660×2000, oil sources1200×680×750 | ||

Weight | (machine) kgs 1850 (oil sources) kgs 300 | (machine) kgs 1850/2100 (oil sources) kgs 300 | (machine) kgs 2800 (oil sources) kgs 300 | ||

Power supply | 3.0KW 380V,50HZ | 3.0KW 380V,50HZ | 3.0KW 380V,50HZ | ||

Main Features

# Working cylinder-piston adopts gap seal, with small frictional force;

# The oil pump has low noise, stable performance and long service life;

# Independent hydraulic chuck oil source and the chucking force can be adjusted;

# Proportional servo valve with quick action response and the demand for the oil quality is low;

# The performance of the sensor is stable with high accuracy;

# The resolving capability is high without grading in the whole measurement range;

# Having the functions of automatic zero setting,automatic calibration, automatic diagnosis and automatic storage, etc.

# The automatic control of constant test force, constant deformation, constant displacement, even rate of stressing and even rate of strain is realized and impact free switch-over is realized in the test;

# Having protection functions for over current, over speed, over-test force and over stroke,

# The oil pump has low noise, stable performance and long service life;

# Independent hydraulic chuck oil source and the chucking force can be adjusted;

# Proportional servo valve with quick action response and the demand for the oil quality is low;

# The performance of the sensor is stable with high accuracy;

# The resolving capability is high without grading in the whole measurement range;

# Having the functions of automatic zero setting,automatic calibration, automatic diagnosis and automatic storage, etc.

# The automatic control of constant test force, constant deformation, constant displacement, even rate of stressing and even rate of strain is realized and impact free switch-over is realized in the test;

# Having protection functions for over current, over speed, over-test force and over stroke,

STANDARD CONFIGURATIONS

Applicable standard

# GB/T 2611-2007 "General Technical Requirements for Testing Machines";

# JB/T 7406.1-1994 "Testing Machine Terminology Material Testing Machine";

# GB/T 16826-2008 "Electro-hydraulic servo universal testing machine";

# GB/T 16825.1-2008 "Inspection of Static Uniaxial Testing Machines Part 1: Inspection and Calibration of Force Measuring Systems of Tensile and (or) Compressive Testing Machines";

# GB/T 22066-2008 "Evaluation of Computer Data Acquisition System for Static Uniaxial Testing Machines"; # JJG 139-2014 "Tensile, Compression and Universal Material Testing Machines";

# JB/T 6146-2007 "Extensometer Specifications";

# JB/T 6147-2007 "Technical Requirements for Testing Machine Packaging, Packaging Marking, Storage and Transportation";

# GB/T 228.1-2010 "Metallic Materials Tensile Test Part 1: Test Method at Room Temperature";

# GB/T 7314-2017 "Metallic Materials Compression Test Method at Room Temperature";

# GB/T 232-2010 "Metallic Material Bending Test Method";

# ASTM A370 Standard Test Methods and Definitions for Testing Mechanical Properties of Steel Products

Equipment operation monitoring system

The equipment operation monitoring system is a subversive improvement made by our company to the original strong current circuit, adding phase sequence, phase loss self-inspection indication function, electrical overcurrent, overload and other protection functions, so that the equipment operation is safe and reliable

Compact structure

The oil cylinder of the main engine goes down, and the double-space adjustable structure facilitates the completion of tests on samples of different sizes.

Automatic clamping

The fixture adopts a fully open inclined block hydraulic clamping structure, and the chuck force can be adjusted in due course.

Good output force and high control precision. Easy to use and higher stability. The system runs smoothly and is automatically adjusted through the rotation of the sprocket and the screw to drive the beam to move up and down.

It can be applied to tensile, compressive, bending, shearing, peeling, tearing and other force tests of materials. After the test, it can be automatically stored with high efficiency, fast and flexible operation. Automatic generation of formed samples

External stand-alone controller and external handheld control box

A new generation of dedicated controller for static testing machines; integrating measurement, control, and transmission functions into one, highly integrated signal acquisition, signal amplification, data transmission, and servo valve drive units, and adding an external manual control unit for the testing machine's measurement, Control and operation provide a new solution, and USB data transmission fully supports notebook computers, tablet computers, and desktop computers; it is an important part of leading the development of testing machine technology.

It can control the rise and fall of the moving beam and oil cylinder, the clamping and loosening of the jaws, and has the emergency stop function of the equipment, which makes the sample clamping more convenient and the operation easier

Hydraulic universal testing machine measurement and control software

The measurement and control of the hydraulic universal testing machine adopts DSP technology and neuron adaptive control algorithm to realize multiple closed-loop control modes such as constant-rate test force, constant-rate cylinder displacement, and constant-rate strain. The control methods can be combined arbitrarily and switched smoothly. Realize data networking and remote control functions.

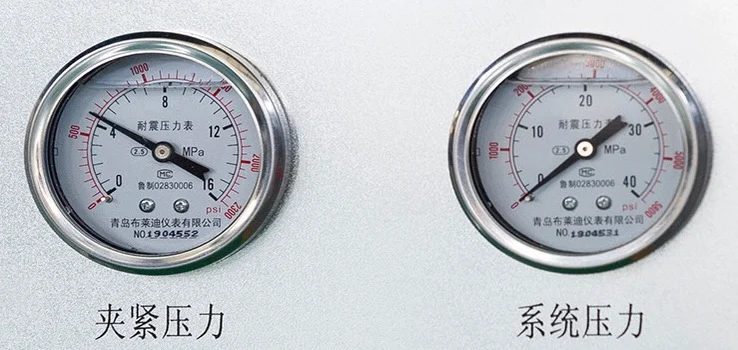

Pressure monitoring instruments

Real-time display of the differential pressure starting pressure, system pressure and clamping pressure of the servo oil source to ensure the normal operation of the equipment.

Packing & Delivery

Our Clients

Installation Requirements and Maintenance

Use and Maintenance

1. Operators must carefully read the host manual, software manual and test standards; they must follow the operating procedures and operate in the correct way;

2. When testing every day, start the equipment and preheat for 10 minutes, especially in winter when the temperature is low; after the test, shut down in the correct order and cut off all power supplies;

3. The operator should clean up the iron slag remaining on the clamping surface of the jaws and the jaw seat every day, so as not to affect the durability of the equipment; the vibration after the sample is broken may cause the fasteners in the jaws to loosen, and regular inspection is required. Check to avoid large losses due to loose fasteners;

3. The screw and the transmission part should be lubricated regularly to prevent dry friction from causing damage to the transmission system;

4. If self-made test auxiliary tooling, the original main structure of the product must not be changed or damaged during installation;

5. If there is an abnormal situation during work, the power supply should be cut off immediately to stop the testing machine from running.

Installation requirements and foundation

1. Personnel preparation: Arrange operators who are proficient in the use of computers, and it is easier for personnel with a measurement operator certificate to master;

2. Item preparation: install a three-phase five-wire air switch on the wall closest to the oil source of the equipment; HM46 anti-wear hydraulic oil 50 liters;

3. Foundation production: The foundation is as shown in the figure below. The convenience of maintenance and overhaul should be fully considered when planning the installation location of the equipment; it is recommended to reserve a space of 500-800mm away from obstacles on the rear and left and right sides of the equipment; the front of the equipment should be kept no less than 2000mm Operating space; when the thickness of the original concrete foundation at the installation position is more than 150mm, you can use a water drill to drill holes according to the size of the foundation drawing; if the foundation thickness is less than 150mm, please install according to the drawing;

4. Equipment in place: The newly built foundation can be used normally after solidification for more than 7 days. After the host is in place, place the level on the workbench to adjust the level of the host. After leveling, pour cement mortar into the four anchor screw holes. The anchor nuts can only be tightened after the cement in the anchor screw holes has solidified.

We still have more similar models available, please don't hesitate to send us inquiries for further discussion, we are in this field for more than 15 years, professional advice can be provided.

Servo hydraulic steel tensile testing machine tensile testing machine

Servo hydraulic steel tensile testing machine tensile testing machine

Servo hydraulic steel tensile testing machine tensile testing machine

You May Like

Not exactly what you want? 1 request, multiple quotations Get Quotations Now >>

You May Like

For more detailed information including pricing, customization, and shipping:

Contact supplier

Call Us

Call Us

Call Us

Call Us

Trading Company

|

≤2h

Response Time

The average amount of time supplier took to respond to every buyer’s first message over the past 30 days.

|

|

|

3,000+ for 3 Transactions

The supplier’s transactions conducted via Chovm.com in the past 6 months.

|

|

| On-time delivery rate |